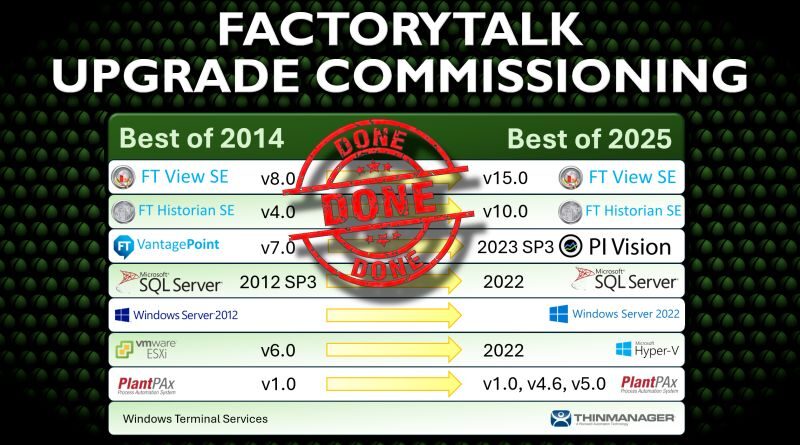

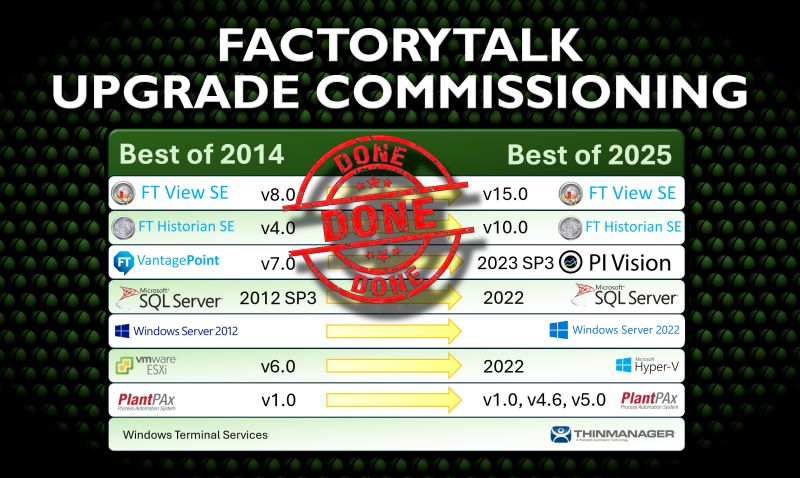

FactoryTalk Upgrade – Best of 2014 to Best of 2025

Finally got the go-ahead to upgrade a system I installed back in 2014, and the results are sweet. Zero downtime, more speed, less resources for the plant thanks to some clever application of tools that avoided a full re-validation.

This virtual infrastructure was Phase 1 to clear the way for new equipment and retrofitting existing equipment with modern PLCs. The whole site is shooting for upgrades to be completed in 2026.

The biggest jump was moving from VMware ESXi to Hyper-V. With the Broadcom/VMware uncertainty, upgrading the virtual servers and SAN made Hyper-V a much more stable choice.

Turned out not to be a big deal for the upgrade. Time will judge on supportability as Hyper-V’s management tools are still a bit lacking compared to vCenter.

To avoid re-validating the system, we stuck to a rigid system of documenting the commercial-off-the-shelf process to upgrade both the applications and operating systems in place.

Errors that came up in the automatic conversion process were documented, manually addressed, and then added to the site acceptance testing.

The best decision, one I’ll post about later, was a side-by-side production startup with the operators: one screen on the new system, one on the old.

I originally planned this as a way to address “That’s not the way it used to work”. It totally came up and quickly addressed that human memory is fallible.

But, FT View SE v15 is WAY faster than v14 and lightspeed faster than the existing v8. Side by side, no comparison.

Even with the really old PlantPax v1 global objects, screens that took 2+ seconds to populate were all under 1sec when pre-compiled. It just “felt” snappier.

If you have the means, I highly recommend an upgrade.

Hit us up, we’ll get it done with minimal impact to your production. (especially you all still on VantagePoint!)